IGBT Heat Sink Dealers in Delhi NCR

2025-08-02IGBT (Insulated Gate Bipolar Transistor) modules play a critical role in inverters, UPS units, EV chargers, and industrial drives. But they generate plenty of heat—efficient thermal dissipation is henceforth a must. That's where IGBT heat sink systems step in.

In Delhi NCR, professional IGBT heat sink dealers provide high-performance thermal solutions specifically designed for Indian conditions—keeping electronics cool, efficient, and reliable. Under climate stress and heavy workloads, choosing the right heat sink minimizes failure and maximizes lifespan.

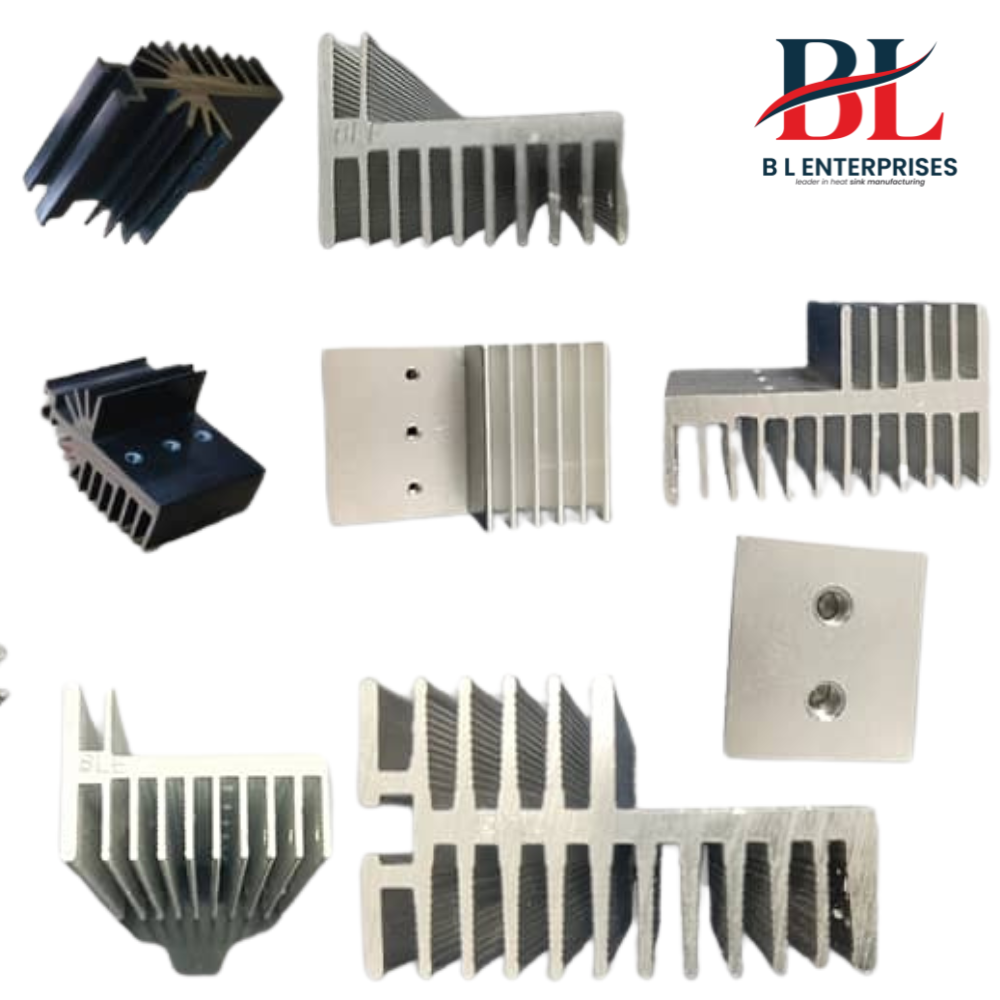

Among reliable local vendors is BL Enterprises, recognized for providing precision-engineered IGBT heat sinks and maintaining consistent thermal management performance.

Why Choose IGBT Heat Sink Dealers in Delhi NCR?

Local Climate Expertise

Delhi NCR's hot, dusty climate requires heat sinks that are capable of withstanding high ambient temperatures. Locally based dealers recognize this and specify materials and design with this in mind.

Quick Delivery & Support

Regional dealers carry standard profiles and are able to deliver fast—ideal for emergency retrofit, replacements, or new installs.

Custom Options & Flexibility

Whichever it is—fin height, base thickness, or orientation in relation to airflow within an enclosure—local dealers are willing to accommodate custom design and small batch production.

Cost Savings

By purchasing locally, consumers bypass import fees, freight costs, and lead times—making high-quality heat sinks less expensive and more available.

Technical Knowledge

Well-connected dealers guide buyers through considerations such as junction-to-ambient thermal resistance (RθJA), airflow rate, hardware for mounting, and performance standards—guaranteeing best-in-the-real-world performance.

What Are IGBT Heat Sinks & Why Do They Matter?

IGBT modules switch high currents and voltages in power electronics, generating heat during conduction and switching states. Uncontrolled excess heat can:

-

Damage semiconductor junctions

-

Cause thermal shutdowns or failure

-

Decrease efficiency and lower lifespan

An optimally designed IGBT heat sink carries heat and dissipates it to ambient air, often utilizing:

-

Extruded aluminum fins for passive cooling

-

Copper inserts for improved conductivity

-

Surface treatments such as anodization for corrosion protection

-

Internal mounting points for clip-on modules or TIM (thermal interface materials)

Typical Types and Uses

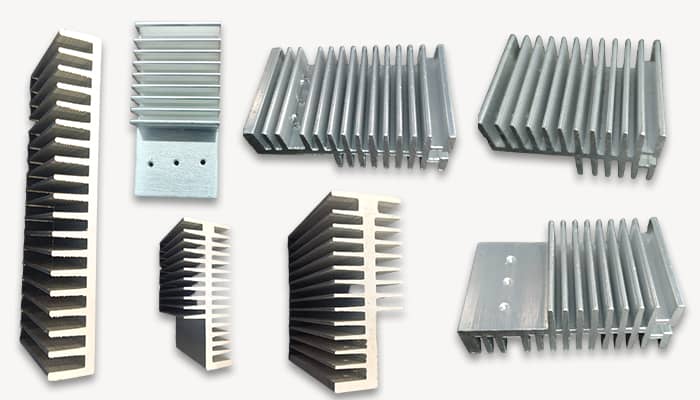

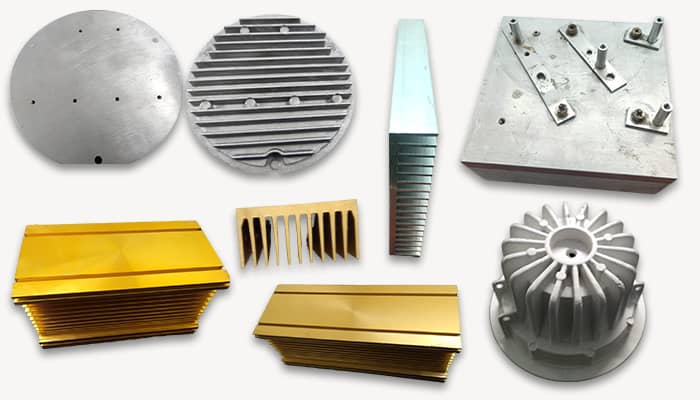

• Extruded Aluminum Heat Sinks

Standard extrusions with flat base and extended fins—easy and inexpensive for most inverters and UPS configurations.

• Skived or Stamped-Copper Inserts

Heat sinks with inserted copper pins for increased thermal conductivity in heavy thermal environments.

• Custom Heat Sink Assemblies

Special solutions for non-conforming module widths or tight enclosures—usually paired with forced flow through fans.

• Clip-On Module Heatsinks

Stand-alone sinks with clips for mounting, perfectly suited for quick assembly in IGBT stack modules or power electronics racks.

These heat sinks are utilized in solar inverters, EV fast chargers, industrial motor drives, evacuation systems, UPS backups, and traction drives.

What to Expect from Dealers in Delhi NCR

Informed Thermal Consultation

Dealers usually start with questions regarding power ratings, anticipated junction temperatures, airflow pathways, and enclosure specifications to size correctly the heat sink configuration.

Sample Support

Good dealers can provide prototypes or sample pieces for preliminary testing to confirm thermal performance prior to bulk purchase.

Design Iteration

Dealers, on the basis of client feedback, modify fin sizes, material thickness, or mounting plane to accommodate compact configurations or airflow restrictions.

Post-Sale Assistance

Some resellers can provide occasional thermal testing or replacement part availability—crucial for uptime-critical operations.

Flexibility on MOQ

Resellers typically take small volume orders—perfect for startups or limited-volume OEM projects—as well as larger batch orders with volume discounts.

Local Real-World Use Cases

-

A Noida backup UPS supplier upgraded to copper-insert sinks, custom-designed to reduce junction temperatures by 15⯰C and improve module reliability.

-

A Ghaziabad EV charger company retrofitted enclosures with small-sized heat sinks optimized to passive airflow for enhanced heat management under continuous usage.

-

Solar inverter manufacturers with local sources for sinks could rapidly cross-match part numbers and lower project lead times from import cycles.

Downtime and warranty claims are paid for by delays or ill-fitting heat sinks—local dealers minimize risk significantly with reduced procurement cycles and local support.

Smooth Keyword Integration

The content typically includes IGBT heat sink , Delhi NCR dealers, and IGBT heat sink dealers—carrying a balance between search relevance and readability, and providing useful insight.

FAQs: IGBT Heat Sink Selection in Delhi NCR

1. How do I select the proper IGBT heat sink for my module?

Consider the power dissipation of the module, ambient temperature, airflow conditions, and mounting real estate. Dealers can suggest sinks on the basis of RθJA targets to ensure safe junction temperatures.

2. Is a copper insert superior to an all-aluminum heat sink?

Copper inserts enhance thermal conductivity at the expense of cost. In high-current designs, the compromise is usually acceptable. In low-power modules, optimized aluminum with fins might be adequate.

3. How much temperature drop can I realize from a heat sink upgrade?

Good heat sinks can lower module temperature by 10–20⯰C, depending on airflow, sink size, and thermal interface material used.

4. Do dealers provide installation accessories?

Most provide thermal pads or pastes, mounting clips or screws, and can recommend adhesive or screw-down attachment procedures to promote good thermal contact.

5. Are custom-designed heat sinks available with low order quantities?

Yes. Most Delhi NCR IGBT heat sink dealers support small MOQ orders and can ship custom profiles or small quantities for pilot deployments or prototyping.

Selecting the Appropriate Dealer

-

Request thermal performance information or simulation output

-

Verify material quality and finish (anodized aluminum, copper inserts)

-

Ask about lead times, MOQ, and engineering assistance

-

Ask for sample testing or fit checks prior to full orders

-

Ensure after-sales service and spare sink availability

Inspecting showrooms or workshops in industrial centers such as Greater Noida or Noida Sector 63 allows one to evaluate workmanship and quality in person.

Spotlight: BL Enterprises

One of the renowned IGBT heat sink distributors in Delhi NCR, BL Enterprises is known for its customized solutions—ranging from extruded aluminum sinks to copper-improved designs for inverters, EV chargers, and UPS units. With thermal simulation assistance, adaptable manufacturing, and knowledge of Indian ambient conditions, they have gained a strong reputation among integrators and OEMs.

Conclusion

With increasing adoption of power electronics in solar, EV, industrial, and UPS applications, heat management becomes mission-critical. Top IGBT heat sink distributors in Delhi NCR provide customized thermal solutions—engineered to local conditions, supported in quick supply and technical assistance.